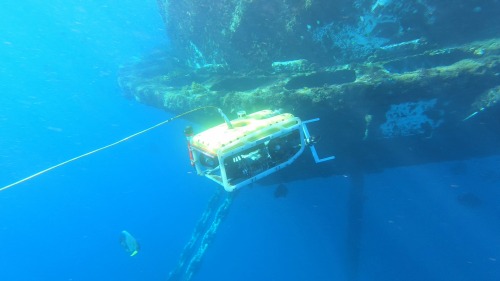

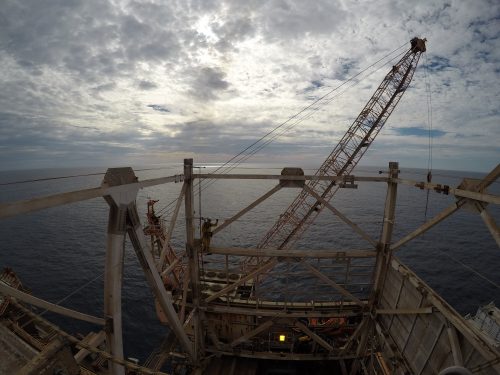

Vertech provides a complete range of inspection, integrity management and specialist brownfield project solutions to the offshore oil and production sector. We pride ourselves on delivering high-quality, innovative solutions to even the most complex problems. Our inspections allow our clients to meet statutory obligations whilst providing valuable data to evaluate and monitor the condition of production assets as an enabler for effective and efficient maintenance planning. Our brownfield project teams include multidisciplinary, high mobility, IRATA Rope access tradesmen who provide intelligent solutions and best-in-class delivery of technically challenging projects.